ADHISAKTHI is well experienced to design and deliver toilet soap manufacturing facility in a state of the art standard.

Following machinery are supplied to perform individually or as a complete plant.

- Sigma mixer

- Noodler / Refiner

- Triple roll mills

- Duplex vacuum plodder

- Bar Cutting machine

- Toilet Soap Stamping machine

- Soap packing machine

- Cartoning machine

- Auto case packer

Options :

Options :

Fully Automatic Toilet Soap Plat

- Automatic raw material elevation

- Process Automations and batch weighing systems

- Direct feed of soap to stamping and packaging lines with auto recycling.

- End of line automations

Mechanised Toiled Soap Plant

- Bucket elevator noodle feeding

- Direct feed of soap to stamping and packaging line with auto recycling

Basic Plant

- Only Basic Machinery will be supplied

- Hand stamping or foot stamping machine.

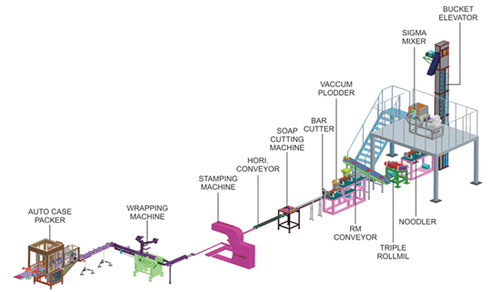

TOILET SOAP PLANT FINISHING LINE:

- Soap making from Soap Noodles comprising of the following stages

- Noodes along with additives will be mixed in the sigma mixer between 20 minutes to 30 minutes based on customer preference.

- Mixed mass from the sigma mixer is fed to the plodder for refining.

- The refined soap is fed to the triple roll mill 2 pass or 4 pass depending upon customer requirements and taken out as flakes.

- The flakes are fed to the duplex vacuum plodder and taken out as bars of required size

- Bar from the plodder is cut to desired size and stamped according to the shape required

- Stamped cake is wrapped or carton packed depending upon packaging design preferred Finally fed to the master carton

SALIENT FEATURES OF MECHANISED PARTIAL AUTOMATIC TOILET SOAP PLANT

- Sigma mixer is placed on the platform to enable material flow by gravity

- Soap Noodle is either lifted by bucket elevator or through electric hoist or manually as preferred

- Entire mixed mass from sigma mixer is fed to Noodler / Refiner

- Refined soap mass is fed to the Triple roll mill where it is flaked out

- Flaked material is lifted by conveyor to the Duplex Vacuum Plodder

- Bar cutter cuts the bar to set repeat lengths

- Soap cutter is used to cut the soap to billets matching to the final size

- Billets are fed to automatic stamping machine or manual stamping machine

- Stamped cakes are either carton packed or soap wrapped

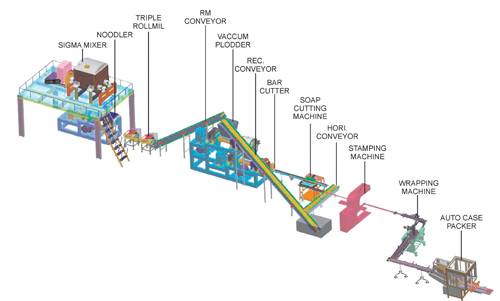

SALIENT FEATURES OF FULLY AUTOMATIC TOILET SOAP PLANT:

- Noodles elevated by bucket elevator / Pneumatically to Silo kept above the sigma mixer

- Based on formula, noodles weighed in the weigh hopper automatically and fed to the sigma mixer

- Material from sigma mixer is dropped to multiscrew conveyor

- Multiscrew conveyor uniformly feeds material to noodler plodder for refining

- Two passes of Triple roll mills to adequately shear the material to a smooth mass without grits

- Duplex vacuum plodder to extrude the bars

- Auto bar cutter and fully automatic recycling systems

- Capacity stamping machine

- Soap wrapping or Carton packing

- Auto direct infeed system from plodder till case packer

- Auto case packer system

Both the above options need to have water chilling plant ( 5 deg ) for circulation in the cooling water jackets of processing machinery and glycol chilling plant ( - 27 deg ) for circulation in stamping dies.

SEMI AUTOMATIC TOILET SOAP PLANT / PILOT PLANT ( COST EFFECTIVE)

- Only critical machinery like sigma mixer, one triple roll mill and non vacuum plodder are used Stamping is done manually.

- Finish of the soap will be comparatively lesser than the one coming out from sophisticated lines

ASPRO QUOTES ONLY THE MAIN LINE MACHINERY ALONE AS A STANDARD QUOTING PROCEDURE. IF THE CUSTOMER INTENDS TO BUY ALL OTHER RELATED EQUIPMENTS AND UTILITIES, DEPENDING UPON THE CUSTOMER REQUIREMENTS QUOTATION WILL BE SUBMITTED.

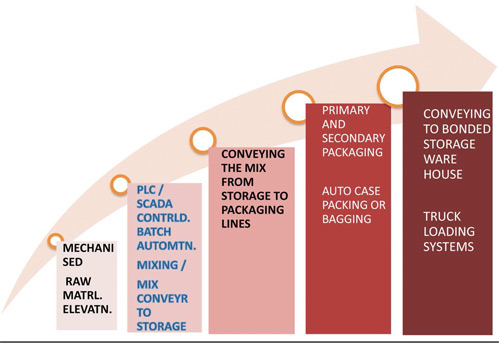

ASPRO'S EXCLUSIVE:

TOTAL SOLUTION FOR PROCESS AND PACKAGING AUTOMATION TILL END OF LINE

** Quote for complete automation will be submitted only on customer requests **

| Model |

Description |

TSP-25-MINI |

Basic line of machinery |

TSP-25-PP-VAC |

Basic line of machinery with vacuum plodder |

TSP-75-MINI |

Basic line of machinery with hand stamping and pneumatic cutting mc |

TSP-150-Medium |

Basic line of machinery with vacuum plodder hand stamping and pneumatic cutting mc |

TSP-150-STD |

Complete line of equipment from noodler, duplex plodder, manual stamping machine and chiller |

TSP-150-AUTO |

Standard line with automatic stamping machine and glycol chiller |

TSP-250-MINI |

Basic toilet soap machinery with hand stamping machine |

TSP-250-STD |

Standard machinery line with automatic stamping and cartoning machine |

TSP-250-AUTO |

Mechanised layout with automatic stamping and cartoning machine |

TSP-600-STD |

Basic line of machinery for the finishing line. |

TSP-600-AUTO |

Mechanised layout with auto link up system on a standard finishing line |

TSP-600-FL-AUTO |

Fully automatic line with case packing and RM batch weighting system |

TSP-1200-STD |

Basic line of machinery for toilet soap finishing line |

TSP-1200-Auto |

Mechanised layout with automatic stamping, packing and automated link up |

TSP-1200-Fl- Auto |

Fully automatic machinery for toilet soap line with RM elevation and End of line automation |

TSP-2000-STD |

Basic standard line of machinery with mechanised link up system for packing. |

TSP-2000-AUTO |

Mechanised layout with automatic stamping and cartoning machine with end of line automation. |

TSP-2000-FL-AUTO |

Fully automatic toilet soap line with automatic raw material feeding and end of line automation. |

| Production rate depends upon the material characteristics |

Specifications are subject to change as a part of continuous improvement.

- Pneumatic powder elevators and batch automation systems are given as per special requirement from customer.

- Cost of platforms, pipelines, electrical, change part cost and other equipments not specified here are extra.

|